Modular vs Self-Contained Ice Machine: How to Choose for Volume

September 17, 2025

I Tested 5 Brands—The Best Walk-In Cooler Revealed

September 18, 2025As a restaurant owner, I’ve seen firsthand how a reliable walk-in cooler can be a game-changer for food safety and inventory management. However, with so many options available, selecting the right one can be daunting. Did you know that a well-designed refrigeration unit can help reduce food waste by up to 20%?

Choosing the right refrigeration unit is crucial for maintaining the quality and safety of your products. Depending on your restaurant’s specific needs, you may require a cooler that can maintain a consistent temperature above 35°F or a freezer that can keep products frozen at -10°F or below.

With various types and sizes of walk-in coolers available, it’s essential to consider your restaurant’s unique requirements and budget constraints. What are the key factors to consider when selecting the best walk-in cooler for your restaurant?

Key Takeaways

- Understand the different types of walk-in coolers and their applications.

- Determine the ideal size and layout for your restaurant’s needs.

- Consider the importance of temperature control systems.

- Learn how to optimize energy efficiency and reduce costs.

- Discover the benefits of proper installation and maintenance.

Understanding Walk-In Cooler Types and Their Benefits

Navigating the options for walk-in coolers requires a clear understanding of the types and their respective advantages. As a restaurant owner, understanding your needs is crucial in making an informed decision.

Prefabricated Walk-In Coolers: Convenience and Flexibility

Prefabricated walk-in coolers offer a convenient solution for restaurants needing a quick installation. These units are manufactured in a factory and assembled on-site, providing flexibility for businesses that may need to relocate or adjust their layout. Prefabricated walk-in coolers are ideal for restaurants with limited space or those that anticipate future changes.

Built-In Walk-In Coolers: Customization and Permanence

Built-in walk-in coolers are a popular choice for businesses requiring a customized cooling solution. These walk-in coolers are constructed with insulation covered by structural tiles on the walls and floors, providing excellent temperature retention and efficiency. The key advantage of built-in walk-in coolers is their ability to be tailored to your exact specifications, allowing you to design a cooling space that perfectly fits your business’s space and needs.

- Superior customization options for unique spatial constraints or specific design requirements.

- Ideal for restaurant owners who own their buildings and plan for long-term operation.

- Better insulation and energy efficiency compared to prefabricated units.

- Aesthetic advantages, as they can be finished to match your kitchen’s design.

- Designed to maximize every inch of available space, fitting into awkward corners or unusual layouts.

Indoor vs. Outdoor Walk-In Coolers: Making the Right Choice

Selecting the right location for your walk-in cooler, whether indoors or outdoors, is vital for optimizing your restaurant’s operations. The decision between indoor and outdoor installations can significantly impact your restaurant’s efficiency and costs.

Factors to Consider for Indoor Installation

When installing a walk-in cooler indoors, it’s crucial to consider the available space and the potential impact on your restaurant’s layout. Indoor installations require careful planning to ensure that the unit fits comfortably and does not obstruct workflow or customer movement.

Outdoor Installation Requirements

Outdoor walk-in coolers offer more flexibility in terms of location, allowing for installation near loading docks or production areas. However, they are more exposed to environmental factors, which can lead to increased wear and tear and potentially higher maintenance costs. The heat generated by outdoor units remains outside, reducing the strain on indoor HVAC systems.

Comparing the Pros and Cons

The choice between indoor and outdoor walk-in coolers depends on several factors, including space availability, efficiency considerations, and overall costs. Here’s a comparison:

| Feature | Indoor Walk-In Cooler | Outdoor Walk-In Cooler |

|---|---|---|

| Space Flexibility | Limited by indoor layout | More flexible, can be near loading docks |

| Environmental Impact | Protected from weather conditions | Exposed to weather, potentially increasing wear and tear |

| Energy Efficiency | Can be more efficient in controlled environments | May require additional weatherproofing, affecting initial costs |

| Installation Complexity | May require alterations to indoor structures | Generally simpler installation |

By weighing these factors, you can make an informed decision that best suits your restaurant’s needs, ensuring optimal efficiency and minimized costs.

Sizing Your Walk-In Cooler Correctly for Restaurant Needs

Selecting the perfect walk-in cooler size is essential for maintaining the quality and safety of your restaurant’s perishable goods. The right size ensures that you have adequate storage without wasting valuable kitchen space.

Assessing Your Storage Requirements

To determine the ideal size for your walk-in cooler, start by assessing your current storage needs. Consider the types and quantities of food you store, as well as any specific storage requirements, such as separate compartments for meat, dairy, or produce. Accurate assessment is key to avoiding under or over-sizing your cooler.

Planning for Future Growth

It’s also crucial to plan for future growth. As your restaurant expands, your storage needs will likely increase. Consider potential increases in menu offerings, customer base, or catering services when sizing your walk-in cooler. Future-proofing your cooler can save you from costly upgrades or replacements down the line.

Standard Sizes vs. Custom Dimensions

Walk-in coolers come in standard sizes (small, medium, large), but you may require custom dimensions to fit your kitchen layout or specific needs. Norlake, a reputable manufacturer, uses actual sizing, providing precise dimensions that can add extra space for shelving. Understand the cost implications and lead time differences between standard and custom units to make an informed decision.

By carefully assessing your storage requirements, planning for future growth, and understanding the options available, you can choose a walk-in cooler that perfectly meets your restaurant’s needs. Whether you opt for a standard size or custom dimensions, the right cooler will enhance your kitchen’s efficiency and help maintain the quality of your food.

Essential Walk-In Cooler Buying Tips for Restaurant Owners

Choosing the right walk-in cooler is a crucial decision that can significantly impact your restaurant’s efficiency and bottom line. As you navigate the process, there are several key factors to consider to ensure you make an informed decision.

Balancing Budget with Quality

When investing in a walk-in cooler, it’s essential to strike a balance between your budget and the quality of the unit. While it may be tempting to opt for the cheapest option, consider the long-term costs and benefits of a high-quality walk-in cooler. A reliable unit from a reputable manufacturer like Norlake can provide years of service, reducing the need for costly repairs and replacements. Be sure to evaluate the costs of different systems and options to find the best value for your restaurant.

Understanding Energy Efficiency Ratings

Energy efficiency is a critical consideration when selecting a walk-in cooler. Look for units with high energy efficiency ratings, as they can significantly reduce your energy costs over time. Understand the different ratings and certifications, such as those provided by the U.S. Environmental Protection Agency, to make an informed decision. By choosing an energy-efficient walk-in cooler, you can minimize your environmental impact while also saving on your utility bills.

Evaluating Warranty Options

A comprehensive warranty is vital when investing in a walk-in cooler. Norlake, for instance, offers an industry-leading warranty on their walk-in coolers and freezers, with 15 years on panels and 18 months on parts and labor. When evaluating warranty options, consider the length of coverage, what’s included, and any exclusions. Compare the warranty offerings between manufacturers to ensure you’re getting the best protection for your investment. Understanding the difference between parts-only and parts-and-labor warranties can also help you make a more informed decision.

| Warranty Component | Norlake Warranty | Industry Standard |

|---|---|---|

| Panels | 15 years | 5-10 years |

| Parts and Labor | 18 months | 12 months |

As noted by industry experts, “A comprehensive warranty can provide peace of mind and protect your investment in a walk-in cooler.” By carefully evaluating your options and choosing a reputable manufacturer, you can ensure that your walk-in cooler provides years of reliable service.

Panel Construction and Insulation: What You Need to Know

To ensure optimal performance and energy efficiency, it’s essential to understand the panel construction and insulation options available for walk-in coolers. The right combination can significantly impact your restaurant’s bottom line by reducing energy costs and maintaining food safety.

Understanding R-Values and Their Importance

The R-value measures the thermal resistance of insulation, indicating its ability to resist heat flow. A higher R-value means better insulation performance. For walk-in coolers, a high R-value is crucial to maintain consistent temperatures and reduce energy consumption. When selecting a walk-in cooler, look for panels with high R-values to ensure optimal energy efficiency and food safety.

Comparing Insulation Materials: Polyurethane vs. Polystyrene

Two common insulation materials used in walk-in coolers are polyurethane and polystyrene. Polyurethane foam offers superior insulation properties and is often used in high-performance walk-in coolers. Polystyrene, while less expensive, may not provide the same level of insulation as polyurethane. When choosing between these materials, consider factors such as energy efficiency, cost, and the specific needs of your restaurant.

Panel Construction Types: Soft-Nose vs. High-Density Rail

Walk-in coolers typically use either soft-nose or high-density rail panel construction. Soft-nose construction features full foam panels that provide an airtight seal and high R-value, offering flexibility in installation and better thermal resistance. High-density rail construction, while durable, may have gaps at the edges that require additional sealing. Understanding the differences between these construction types is vital for selecting a walk-in cooler that meets your needs.

In conclusion, the panel construction and insulation of a walk-in cooler are critical factors that impact its performance, energy efficiency, and overall cost. By understanding the different options available, such as R-values, insulation materials, and panel construction types, you can make an informed decision that benefits your restaurant’s operations and bottom line.

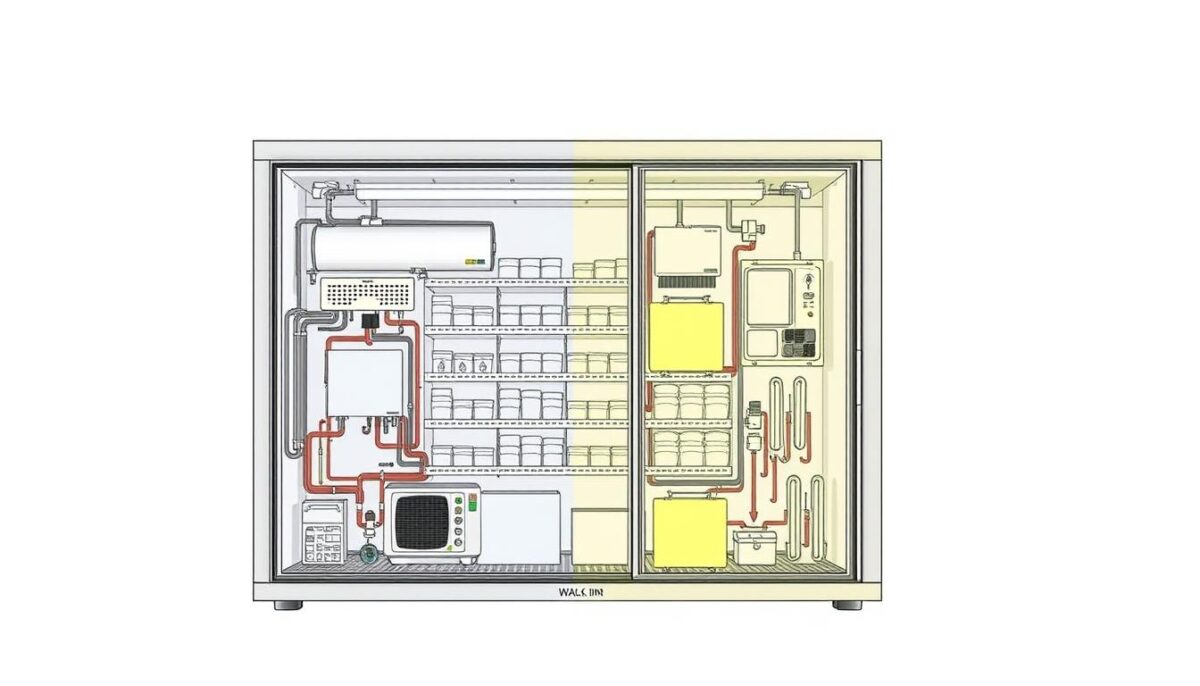

Refrigeration Systems: Choosing the Right Configuration

Selecting the right refrigeration system for your walk-in cooler is crucial for maintaining optimal temperatures and ensuring food safety. The type of refrigeration system you choose can significantly impact your energy consumption, operational costs, and environmental footprint.

Self-Contained vs. Remote Refrigeration Systems

When deciding on a refrigeration system, one of the primary considerations is whether to opt for a self-contained unit or a remote system. Self-contained systems are compact and integrate the refrigeration unit within the walk-in cooler itself, making them suitable for smaller operations or locations where space is limited. On the other hand, remote refrigeration systems offer more flexibility and can be more efficient for larger walk-in coolers, as they allow for the compressor and condenser to be located outside, reducing noise and heat inside the restaurant.

Refrigerant Types and Environmental Considerations

The choice of refrigerant is another critical aspect of your refrigeration system. With the phase-down of hydrofluorocarbons (HFCs) due to their high Global Warming Potential (GWP), it’s essential to consider more environmentally friendly alternatives. Refrigerants like R-290 (propane) and R-744 (CO2) are gaining popularity due to their lower GWP and energy efficiency. R-290, for instance, has a GWP of just 3 and offers excellent cooling performance, making it an attractive option for many businesses looking to reduce their environmental impact.

Understanding the safety classifications of different refrigerants is also crucial. The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) classifies refrigerants based on their flammability and toxicity. For example, R-290 is classified as A3, indicating it’s highly flammable, and thus requires specific safety precautions during handling and installation.

By choosing the right refrigeration system and refrigerant, you can not only ensure compliance with current and future regulations but also improve your restaurant’s sustainability and reduce operational costs.

Flooring Options for Your Walk-In Cooler

Choosing the right flooring for your walk-in cooler is crucial for maintaining a safe and hygienic environment in your restaurant. The flooring in your walk-in cooler is subject to various challenges, including moisture, heavy foot traffic, and the need for frequent cleaning.

Insulated vs. Non-Insulated Floors

When deciding on flooring for your walk-in cooler, one of the first considerations is whether to opt for insulated or non-insulated floors. Insulated floors can help reduce energy costs by minimizing heat transfer between the floor and the cooled space. Non-insulated floors, on the other hand, may be more cost-effective upfront but could lead to higher energy bills over time.

Flooring Materials and Safety Considerations

The choice of flooring material is critical for safety and compliance with food safety regulations. Slip-resistant flooring is essential to prevent accidents, especially in environments where water or spills can occur. Materials like vinyl or epoxy coatings can provide a seamless, easy-to-clean surface that is resistant to chemicals and wear. Additionally, proper drainage is crucial to prevent pooling water, which can lead to slip hazards and hygiene issues.

| Flooring Material | Slip Resistance | Maintenance Requirements |

|---|---|---|

| Vinyl Coating | High | Low |

| Epoxy Coating | High | Low |

| Stainless Steel | Medium | Medium |

For walk-in coolers, NSF Standard 7 requires the use of materials like aluminum or stainless steel for the floor, limiting the choices. It’s essential to balance durability, safety, and cost when selecting the right flooring material for your specific restaurant operation.

Door Types and Accessibility Features

When it comes to walk-in coolers, the door is more than just an entry point; it’s a critical component that affects energy efficiency, safety, and overall functionality. The right door can make a significant difference in your restaurant’s operations.

Standard Swing Doors vs. Sliding Doors

Choosing between standard swing doors and sliding doors depends on your specific needs. Standard swing doors are common and provide easy access, while sliding doors can be more space-efficient. Double gasket doors ensure an airtight seal, reducing energy costs and protecting perishables.

Door Hardware and Safety Features

Door hardware plays a crucial role in both energy efficiency and safety. Critical components include gaskets, hinges, and latching mechanisms. Seamless gaskets simplify assembly and eliminate the need for additional sealants. Safety features like interior release handles are required by code to prevent accidental entrapment. Proper door threshold design and door closure mechanisms also contribute to maintaining consistent interior temperatures and saving energy.

Specialized door features for high-traffic environments, such as kick plates, bumpers, and reinforced viewing windows, can extend the life of your cooler door. By considering these factors, you can select a door that meets your needs and enhances the overall performance of your walk-in cooler.

Temperature Control Systems and Monitoring

Proper temperature monitoring is key to preventing food spoilage and ensuring compliance with food safety regulations. Effective temperature control systems are designed to maintain the internal temperature of your walk-in cooler within safe ranges while reducing energy consumption.

Digital Controllers and Smart Monitoring Options

Modern walk-in coolers often come equipped with digital controllers that offer advanced features such as smart monitoring options. These systems allow for real-time temperature monitoring and can be configured to send alerts to staff members in case of temperature fluctuations.

Temperature Alarms and Safety Features

Temperature alarms are a critical safety feature in walk-in coolers. These alarms can be set up to trigger at specific temperature thresholds, ensuring that staff is notified promptly in case of any issues. Additionally, door ajar alarms can prevent energy waste and temperature fluctuations by alerting staff when the door is left open.

Other important features include backup power systems and battery-operated alarm features that provide protection during power outages. By implementing these systems and following best practices for alarm response protocols, restaurants can protect both food safety and equipment, potentially saving thousands in inventory.

Energy Efficiency Strategies for Walk-In Coolers

Optimizing energy efficiency in walk-in coolers is crucial for reducing operational costs. As a restaurant owner, you can significantly impact your bottom line by implementing the right strategies. Choosing a location that minimizes heat transfer and is close to power and water sources can save on energy costs.

Energy-Saving Components and Features

When it comes to energy-saving components, there are several features to consider. High-efficiency refrigeration systems and LED lighting can significantly reduce energy consumption. Additionally, features like automatic door closers and strip curtains can help maintain the cooler’s internal temperature, reducing the workload on the refrigeration system.

- High-efficiency refrigeration systems

- LED lighting

- Automatic door closers

- Strip curtains

Operational Practices to Reduce Energy Consumption

Implementing operational practices can also significantly reduce energy consumption. By optimizing stocking practices, you can improve airflow and cooling efficiency. This includes proper spacing between products and keeping items away from evaporator fans. Scheduled maintenance procedures like coil cleaning and door gasket inspection can prevent energy waste.

- Optimize stocking practices for better airflow

- Perform scheduled maintenance tasks regularly

- Train staff on proper door usage and product retrieval patterns

By implementing these strategies, you can reduce your walk-in cooler’s energy consumption by 15-30% without requiring any equipment upgrades. A simple energy-saving checklist can help your kitchen staff ensure the walk-in cooler operates at peak efficiency throughout its lifespan.

Food Safety Compliance and Regulations

Your walk-in cooler is a vital part of your restaurant’s food safety plan, directly impacting the quality and safety of your products. Ensuring compliance with food safety regulations is crucial, and your walk-in cooler plays a central role in this effort.

NSF and Health Department Requirements

The National Sanitation Foundation (NSF) and local health departments set strict guidelines for walk-in coolers to ensure food safety. These requirements include proper temperature control, sanitation, and maintenance of the cooler. Compliance with these regulations is not only mandatory but also essential for maintaining customer trust and avoiding costly fines.

- Regular cleaning and sanitizing of the walk-in cooler

- Proper temperature monitoring and recording

- Maintenance of the cooler to prevent equipment failure

HACCP Compliance for Walk-In Coolers

A Hazard Analysis Critical Control Point (HACCP) plan is critical for ensuring food safety in your restaurant. Your walk-in cooler is a key component of this plan, requiring precise temperature control and monitoring. Implementing automated temperature monitoring systems can simplify HACCP compliance, providing reliable and consistent documentation.

Corrective actions for temperature deviations should be established, including decision trees for when food must be discarded.

By integrating walk-in cooler monitoring into your overall food safety management system, you can ensure seamless compliance with minimal staff burden.

Customization Options for Restaurant-Specific Needs

A well-customized walk-in cooler not only optimizes storage space but also improves overall energy efficiency and product safety. To achieve this, several key customization options should be considered.

Shelving and Storage Configurations

Effective shelving and storage configurations are crucial for maximizing the use of space within your walk-in cooler. Options include adjustable shelving units, storage bins, and specialized storage solutions for specific products or items. By tailoring the storage to your restaurant’s needs, you can enhance inventory management and reduce clutter.

- Adjustable shelving for flexible storage arrangements

- Storage bins for organizing smaller items

- Specialized storage for meats, dairy, and other perishable products

Lighting and Interior Accessories

Proper lighting ensures visibility and safety inside the walk-in cooler. LED lighting is particularly effective due to its energy efficiency and long lifespan, even in cold environments. Consider motion-activated lighting to reduce energy consumption when the cooler is not in use.

Additional interior accessories can further enhance functionality, including hanging rod systems, wine racks, and keg storage solutions. Strategic placement of thermometers and humidity monitors helps maintain optimal storage conditions throughout the cooler.

- LED lighting for superior energy efficiency

- Motion-activated lighting to reduce energy consumption

- Specialized interior accessories for enhanced functionality

Installation Considerations and Best Practices

The installation of a walk-in cooler unit is not just about placing the equipment; it’s about ensuring it operates efficiently and effectively. Proper installation is crucial for the optimal performance and longevity of the unit.

Site Preparation Requirements

Before installing a walk-in cooler, it’s essential to prepare the site correctly. This includes ensuring the floor is level, the area is clean and clear of debris, and there is adequate space for the unit and its components. Proper site preparation is key to a successful installation.

Professional vs. DIY Installation

While DIY installation might seem cost-effective, it’s often recommended to opt for professional installation for walk-in coolers. Professionals have the necessary expertise to handle complex tasks such as refrigeration system setup and electrical connections. Manufacturer warranties are often tied to professional installation, making it a safer choice to avoid voiding important protections for your investment.

Understanding the installation process, from initial site assessment to final commissioning, helps in planning and budgeting. It’s also crucial to evaluate installation quotes carefully, identifying what’s included and what might incur additional costs.

Maintenance Tips to Extend Your Walk-In Cooler’s Lifespan

Maintaining your walk-in cooler is crucial for its longevity and performance. Routine maintenance will prolong the life of your walk-in unit and maintain optimal performance.

Regular Cleaning and Inspection Routines

Regular cleaning and inspection are vital to prevent issues with your walk-in cooler. This includes checking the door seals for any signs of wear or damage and ensuring that the temperature control system is functioning correctly. By doing so, you can identify potential problems early on.

- Clean the condenser coils regularly to improve efficiency.

- Inspect the unit for any signs of physical damage or wear.

- Check the door alignment and gaskets for air leaks.

Common Issues and Troubleshooting

Understanding common issues with your walk-in cooler can help you troubleshoot effectively. For instance, if you notice fluctuations in temperature, it could be due to a faulty system or improper door sealing. Regularly checking these components can help prevent major problems.

By following these maintenance tips, you can extend the lifespan of your walk-in cooler and ensure it operates efficiently.

Cost Considerations: Initial Investment vs. Long-Term Value

Evaluating the cost of a walk-in cooler requires considering both initial and ongoing expenses. Your cold storage plays a central role in your operation’s success, directly impacting the quality and safety of your products.

Understanding the Total Cost of Ownership

The total cost of ownership for a walk-in cooler includes the initial purchase price, installation costs, energy consumption, maintenance, and potential repair expenses. To make an informed decision, you must consider these factors to understand the true cost of your investment. Energy-efficient models, although potentially more expensive upfront, can lead to significant savings over time.

- Assess the energy efficiency ratings of different models.

- Consider the cost implications of various financing options.

- Factor in the potential for future repairs and maintenance.

Financing Options and ROI Calculations

Various financing options are available for purchasing a walk-in cooler, including equipment loans, leasing arrangements, and manufacturer financing programs. To determine the best option, you should calculate the return on investment (ROI) for energy-efficient models and consider how tax incentives and utility rebates can reduce your costs. Timing your purchase to take advantage of end-of-quarter or end-of-year manufacturer incentives can also significantly reduce your expenses.

Conclusion: Making Your Final Walk-In Cooler Decision

As you finalize your walk-in cooler decision, it’s essential to revisit the key factors that will impact your restaurant’s efficiency and food storage capabilities. Throughout this guide, we’ve explored various aspects of walk-in coolers, from types and sizes to energy efficiency and installation considerations.

To confidently select the perfect walk-in cooler for your restaurant, prioritize your specific needs regarding size, type, location, and features based on your unique operation and future growth plans. Ensure that your chosen unit balances initial cost with long-term value, considering how energy efficiency and quality construction will pay dividends over the unit’s lifespan.

Proper sizing and installation are critical to ensure your walk-in cooler performs optimally from day one. Consider not just your current needs but your restaurant’s trajectory over the next 5-10 years, ensuring your walk-in cooler investment supports your business growth. By carefully evaluating these factors, you’ll be able to make an informed decision that meets your restaurant’s needs and enhances your overall refrigeration capabilities.

FAQ

What are the key factors to consider when choosing a walk-in cooler for my restaurant?

When selecting a walk-in cooler, I consider factors such as the size of my restaurant, the type of food I serve, my storage needs, and my budget. I also think about the energy efficiency and the type of refrigeration system that will work best for me.

What is the difference between a prefabricated and a built-in walk-in cooler?

Prefabricated walk-in coolers are pre-assembled and can be easily installed, offering convenience and flexibility. Built-in walk-in coolers, on the other hand, are custom-built to fit my specific needs and provide a more permanent solution.

How do I determine the correct size for my walk-in cooler?

To determine the correct size, I assess my storage needs, consider my future growth, and think about the space available in my restaurant. I also consider standard sizes versus custom dimensions to ensure I get the best fit.

What are the benefits of energy-efficient walk-in coolers?

Energy-efficient walk-in coolers can help reduce my energy consumption, lower my utility bills, and minimize my environmental impact. I look for coolers with high energy efficiency ratings and features such as LED lighting and smart monitoring systems.

What type of flooring is best for my walk-in cooler?

For my walk-in cooler, I consider flooring options that are durable, easy to clean, and resistant to moisture. Insulated floors can help reduce energy consumption, while non-insulated floors may be more cost-effective.

How can I ensure food safety compliance with my walk-in cooler?

To ensure food safety compliance, I follow NSF and health department requirements, implement HACCP protocols, and regularly inspect and maintain my walk-in cooler to prevent contamination and ensure proper temperature control.

What are the advantages of digital temperature control systems?

Digital temperature control systems offer precise temperature control, smart monitoring options, and temperature alarms to ensure my food is stored safely. These systems can also help me reduce energy consumption and optimize my walk-in cooler’s performance.

How often should I maintain my walk-in cooler?

Regular maintenance is crucial to extend the lifespan of my walk-in cooler. I schedule regular cleaning and inspection routines, check for common issues, and perform troubleshooting tasks to ensure my cooler operates efficiently and effectively.