True vs Turbo Air: Which Refrigerator Delivers the Best ROI in 2025?

September 15, 2025

4 Image-Killing Mistakes With Glass Door Refrigeration

September 16, 2025In the world of commercial ice makers, finding the right fit for your business can be a chilling challenge. As a business owner, you’re likely no stranger to the importance of a reliable commercial ice maker. In this comprehensive comparison, I’ll analyze five top-performing ice machines that dominate the market today.

I’ll be diving into the world of commercial ice makers to help you find the perfect match for your business needs. My goal is to save you time and money by helping you avoid common purchasing mistakes when selecting a commercial ice maker.

In this article, I’ll explore how each machine performs in real-world settings, from busy restaurants to corporate offices. You’ll discover which ice maker delivers the best combination of reliability, production capacity, and value.

By the end of this article, you’ll understand why one particular ice machine stands head and shoulders above the competition. I’ll share insights from industry experts and business owners who have tested these machines in demanding environments.

Why Your Business Needs the Right Commercial Ice Maker

Selecting the right commercial ice maker is crucial for any business that relies on serving chilled beverages. As I’ve seen firsthand, the right ice machine can transform a business’s operations and customer satisfaction levels. The quality of ice isn’t just about aesthetics; it directly impacts the taste of beverages and the overall customer experience in restaurants and bars.

The Impact of Ice Quality on Customer Experience

Quality ice is essential for maintaining the taste and temperature of drinks. Different types of ice affect drink dilution rates, influencing customer perception of your service. For instance, clear ice is preferred in high-end establishments because it melts slower, keeping drinks cold without diluting them quickly. Water quality and machine maintenance directly impact ice clarity and taste, factors that your customers will notice.

How Ice Production Affects Your Bottom Line

The production capacity of your ice machine, measured in pounds of ice per day, must align with your business’s peak demands to avoid shortages. Insufficient ice production can create bottlenecks during rush periods, affecting service speed and staff efficiency. Investing in the right commercial ice machine can reduce operational costs through improved energy efficiency and reduced water usage.

| Business Type | Average Daily Ice Needs | Recommended Ice Machine Capacity |

|---|---|---|

| Restaurants | 100-200 lbs | 200-400 lbs |

| Bars | 50-150 lbs | 150-300 lbs |

| Hotels | 200-500 lbs | 400-800 lbs |

Understanding your specific business needs is crucial when selecting an ice machine that will serve you well for years to come. By calculating your daily ice requirements based on your business type, customer volume, and specific applications, you can make an informed decision.

Understanding Commercial Ice Maker Types

To select the perfect commercial ice maker, you need to understand the different types and their applications. Commercial ice machines are available in three main configurations: Modular, Undercounter, and Countertop Ice Dispensers. Each type is designed to meet specific business needs, and choosing the right one can significantly impact your operations.

Modular Ice Machines: High Output for Busy Establishments

Modular ice machines, also known as ice machine heads or IMH, are stackable units that come in various sizes, producing between 200 lbs. and 1,900 lbs. of ice per day. These machines are ideal for busy establishments that require high-volume ice production. They work with separate storage bins, maximizing production capacity while offering flexibility in your setup.

Undercounter Ice Makers: Space-Saving Solutions

Undercounter or self-contained units (SCU) combine the storage bin and ice machine, fitting neatly under a standard 40″ high countertop. They produce around 350 lbs. of ice per day, making them perfect for businesses with space constraints. These units provide an excellent balance of production capability and space efficiency.

Countertop Ice Dispensers: Convenience and Hygiene

Countertop ice dispensers are commonly used in healthcare facilities and can produce up to 400 lbs. of ice per day. They offer unique advantages for customer-facing environments, providing both convenience and hygiene benefits. These dispensers are compact and can be placed on countertops, making them ideal for businesses where space is limited.

The type of condenser used in your commercial ice maker, such as air-cooled condensers, can significantly affect the machine’s performance and placement options. Understanding these differences is crucial for making an informed decision that meets your business needs.

Types of Ice and Their Best Applications

The type of ice you choose can be just as crucial as the ice maker itself for your business. Different types of ice serve various purposes, and understanding these differences is key to making an informed decision that enhances customer experience and optimizes your beverage program.

Cube Ice: The Versatile Standard

Cube ice is the industry standard for a reason. It’s produced by a machine called a cuber, and over 80% of ice machines in the U.S. produce this type. Cube ice is versatile and preferred for general-purpose applications in most establishments because it melts slower than other forms, making total consumption lower. This characteristic makes it ideal for premium drinks where minimal dilution is desired.

Half Cube and Dice Ice: Fast Cooling for Beverages

Half cube and dice ice offer faster cooling for beverages while maximizing glass space. Many restaurants and bars prefer this option because it provides a better customer experience by keeping drinks cold without filling the glass with ice. This type of ice is particularly useful in fast-paced environments where quick service is essential.

Nugget Ice: Chewable and Customer-Favorite

Nugget ice, also known as ‘chewblet’ or compressed nugget ice, is soft and chewable. It’s commonly used by healthcare facilities and is gaining popularity among certain fast food restaurants and bars. Customers often request this type of ice specifically because of its unique texture and ability to cool drinks quickly without making them watery.

Specialty Ice: Crescent, Flake, and Sphere

Specialty ice forms like crescent ice, flake ice, and sphere ice cater to specific business needs. Crescent ice, Hoshizaki’s signature type, is known for its unique shape and cooling efficiency. Flake ice is used for packing, preservation, and cooling purposes, often in food displays. Sphere ice is used in premium cocktails for its aesthetic appeal and slow melting rate, making it a favorite among upscale bars and restaurants.

Understanding how different types of ice affect drink presentation, cooling efficiency, and customer experience will help you select the right ice maker for your specific needs. By matching the ice type to your business application, you can enhance customer satisfaction and optimize your beverage program’s efficiency.

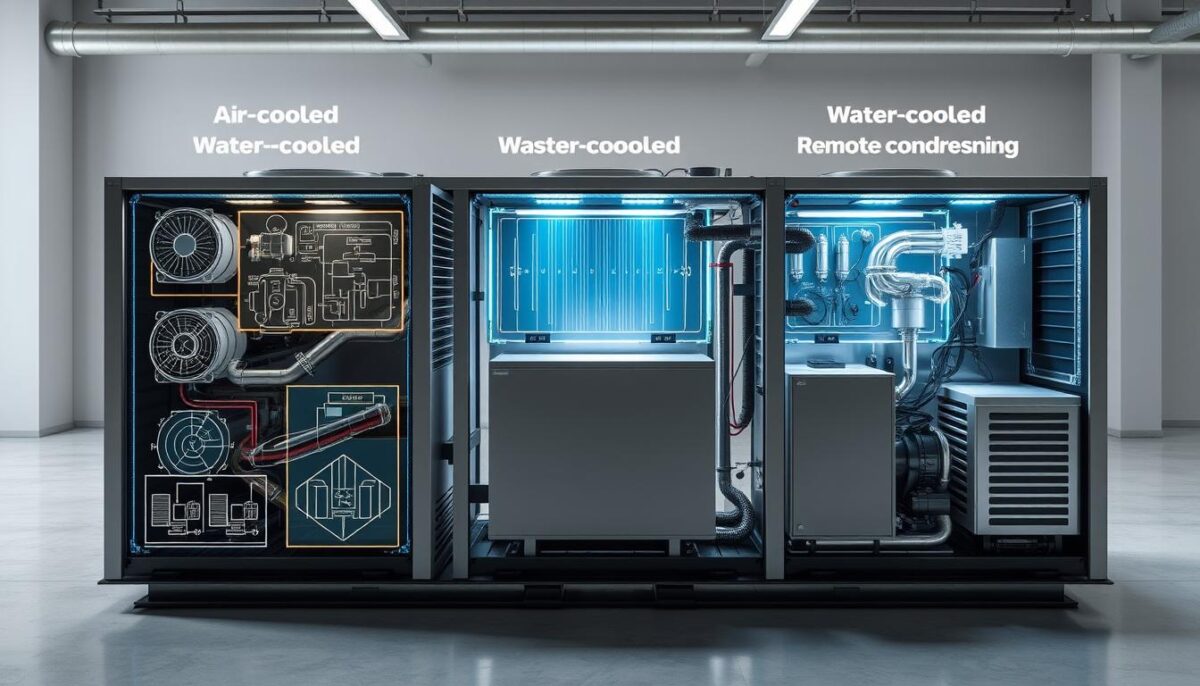

Cooling Systems: Air-Cooled vs. Water-Cooled vs. Remote

Understanding the differences between air-cooled, water-cooled, and remote cooling systems is essential for selecting the best ice maker for your business. The choice of cooling system significantly impacts your ice machine’s efficiency, operating costs, and placement options.

Air-Cooled Condensers: Most Common and Practical

Air-cooled condensers are the most common solution for most businesses due to their practicality and lower water consumption. In an air-cooled condenser, air is blown over the refrigeration lines to draw heat away, using fans and air vents to keep air flowing. This type is ideal for environments where water conservation is a priority.

Water-Cooled Systems: Efficient but Resource-Heavy

Water-cooled systems offer superior efficiency in challenging environments, making them a viable option despite higher water usage. They use water to cool refrigerant vapor, requiring a continual water supply with two separate water lines. While they can be costly in terms of water utility bills, they are typically quieter and more efficient.

Remote Condensers: Quiet Operation for Customer-Facing Areas

Remote condensers are similar to air-cooled condensers but are installed outdoors, usually on a roof. This setup makes the ice machine very quiet, making it an excellent solution for noise-sensitive environments. However, they are typically more expensive to install and maintain.

By understanding the maintenance requirements and operational characteristics of each cooling system type, you can make an informed decision that aligns with your business needs and environment.

Key Factors in Commercial Ice Maker Comparison

To make an informed decision when purchasing a commercial ice maker, it’s essential to understand the critical comparison factors. When evaluating different models, several key elements come into play, directly impacting the performance, efficiency, and overall cost of ownership.

Daily Production Capacity: Matching Your Business Needs

Daily production capacity is a fundamental consideration. It’s crucial to calculate your business needs based on customer volume, usage patterns, and peak demand periods. An ice machine that is either undersized or oversized can lead to operational inefficiencies and increased costs.

Storage Bin Size: Balancing Production and Usage

The storage bin size is equally important as it ensures a steady ice supply during busy periods. Determining the optimal storage capacity involves considering your business type and usage patterns. A well-balanced storage bin size prevents both ice shortages and excessive ice accumulation.

Energy and Water Efficiency: Long-term Cost Considerations

Energy and water efficiency ratings significantly impact your long-term operating costs. When comparing ice makers, look for models with high efficiency ratings and ENERGY STAR certification, which can lead to substantial savings on utility bills and reduce your environmental footprint.

Maintenance Requirements and Sanitation Features

Maintenance requirements vary widely between models and manufacturers. Opt for ice machines with features like antimicrobial components and easy-clean designs to minimize downtime, service costs, and ensure ice quality. Regular maintenance is crucial for the longevity of your commercial ice maker.

By understanding these key comparison factors, you can look beyond the initial purchase price to evaluate the true cost of ownership for different commercial ice makers, ensuring you make a well-informed investment decision that meets your business needs.

- Calculate your daily ice needs based on customer volume and peak demand.

- Balance production capacity with storage bin size for optimal performance.

- Consider energy and water efficiency for long-term savings.

- Evaluate maintenance requirements and sanitation features.

Top 5 Commercial Ice Makers Compared

For businesses seeking to invest in a reliable commercial ice maker, understanding the differences between top models is essential. In this comparison, we’ll analyze five leading commercial ice machines, examining their production capacities, features, and ideal applications.

KoolAire KYT0500A-161: Reliability Champion

The KoolAire KYT0500A-161 stands out for its exceptional reliability and maintenance-friendly design. This air-cooled unit produces up to 550 lbs. of half-cube ice daily, making it ideal for busy restaurants and bars. Its tool-free removable parts simplify cleaning and repairs, reducing downtime and maintenance costs.

Manitowoc SDT3000W-263H “Quadzilla”: Production Powerhouse

The Manitowoc SDT3000W-263H “Quadzilla” is a production giant, capable of producing 3,000 lbs. of ice per day. This model is perfect for large-scale businesses or those with extremely high ice demands. Its robust design ensures consistent performance even in demanding environments.

Hoshizaki KM-1301SAJ: Premium Crescent Ice

The Hoshizaki KM-1301SAJ offers premium crescent ice production, with a daily capacity of up to 1,365 lbs.. This model’s durable stainless steel exterior and efficient evaporator design make it suitable for high-end establishments seeking high-quality ice. The unique crescent ice shape is particularly popular in upscale restaurants and hotels.

Scotsman HID525A-1 Meridian: Sanitary Nugget Ice Solution

The Scotsman HID525A-1 Meridian is designed with sanitation in mind, offering high-capacity nugget ice production of up to 500 pounds daily. Its durable stainless steel construction, low maintenance requirements, and hands-free sensor operation make it an excellent choice for healthcare facilities and businesses prioritizing hygiene.

Manitowoc IYT1500A: Energy-Efficient Performer

The Manitowoc IYT1500A is an energy-efficient commercial ice maker that produces up to 1,660 lbs. of half-size ice cubes per day. Its state-of-the-art 24-hour preventative diagnostics and illuminated easyTouch display ensure optimal performance while minimizing energy consumption. This model is ideal for businesses seeking to balance high ice production with reduced operating costs.

When comparing these top commercial ice machines, factors such as daily production capacity, ice type, energy efficiency, and maintenance requirements become crucial. By understanding the strengths and weaknesses of each model, businesses can make informed decisions that meet their specific needs and enhance their operations.

Best Commercial Ice Makers by Business Type

Businesses across different sectors require ice makers that cater to their specific operational demands. The type of ice maker that suits a restaurant may not be ideal for a hotel or a healthcare facility. As I explore the needs of various industries, it becomes clear that understanding these differences is crucial for making an informed decision.

Restaurants and Bars

Restaurants and bars need high-volume ice production to keep up with peak service periods. They require ice makers that can produce ice quickly, such as half cubes or nugget ice. For small to medium-sized restaurants, compact ice machines with adequate production capacity are essential.

Large restaurants, on the other hand, need high-capacity ice makers that can meet their demanding needs. “The right ice maker can make all the difference in a busy restaurant environment,” as it enables them to serve customers efficiently.

Hotels and Hospitality

Hotels and hospitality businesses require ice makers that offer self-service functionality and aesthetic appeal for guest areas. They need machines that can provide clean ice reliably and have maximum storage capacity. Strategic placement of ice machines throughout the property is also crucial to meet guest needs.

By choosing the right commercial ice maker, hotels can enhance their guests’ experience and create a positive impression.

Healthcare Facilities

Healthcare facilities prioritize sanitation and require ice makers with touch-free dispensing mechanisms. Nugget ice is often preferred in medical settings due to its malleable and chewable nature. Antimicrobial components are also essential in healthcare environments to prevent contamination.

As one healthcare professional noted, “The right ice maker can play a critical role in maintaining patient comfort and safety.”

Offices and Corporate Settings

Offices and corporate settings need ice makers that offer convenience, low maintenance, and sanitary self-service options. Nugget ice is popular in these settings due to its unique characteristics. Moderate ice output and reliability are key considerations for offices.

By selecting the right commercial ice solution, offices can create a welcoming environment for employees and visitors.

The Clear Winner: KoolAire KYT0500A-161

In my analysis, the KoolAire KYT0500A-161 emerges as the leading commercial ice machine, offering a balance of production capacity and maintenance ease. This ice maker produces up to 550 lbs. of half-cube ice daily, making it ideal for busy restaurants and bars.

Why It Outperforms the Competition

The KoolAire KYT0500A-161 stands out due to its exceptional reliability record and user-friendly maintenance features. The tool-free removable components significantly reduce cleaning and service time, resulting in less downtime and lower maintenance costs. Its air-cooled condenser simplifies installation and reduces the need for additional resources.

The machine’s performance metrics, including consistent ice production under varying conditions and long-term durability, put it ahead of competitors. The balance of production capacity and reasonable footprint makes this ice maker versatile enough for most business environments.

| Feature | KoolAire KYT0500A-161 | Manitowoc “Quadzilla” |

|---|---|---|

| Daily Ice Production | 550 lbs. | Higher capacity |

| Maintenance Ease | Tool-free removable parts | More complex maintenance |

Who Should Consider Alternative Options

While the KoolAire KYT0500A-161 is my top recommendation, certain businesses may need to consider alternative options. Very high-volume operations may require the production capacity of the Manitowoc “Quadzilla.” Businesses with specialty ice needs, such as premium cocktail bars or healthcare facilities, might benefit more from machines that produce specific ice types.

For instance, a premium cocktail bar might prefer a machine that produces nugget ice for its chewable texture and aesthetic appeal. Similarly, healthcare facilities may require ice machines with advanced sanitation features to prevent contamination.

Installation and Maintenance Considerations

When installing a commercial ice machine, several critical factors come into play to ensure optimal performance and longevity. A well-planned installation is just the beginning; regular maintenance is equally crucial for maintaining ice quality and machine efficiency.

Space and Utility Requirements

Properspace planningis essential for the installation of your commercial ice machine. Different condenser types have varying clearance requirements, particularlyair-cooled unitsthat need adequate ventilation to operate efficiently. For instance, air-cooled condensers require sufficient clearance around the unit to ensure proper airflow. Additionally, utility connections such as electrical specifications, water line requirements, and drainage considerations must be carefully planned. Forwater-cooled condenser systems, additional plumbing requirements must be met, and compliance with local water usage regulations is necessary.

- Ensure adequate clearance for air-cooled condensers to facilitate proper airflow.

- Plan utility connections, including electrical, water, and drainage requirements.

- Comply with local regulations for water-cooled systems.

Cleaning Schedules and Best Practices

Regular maintenance is vital for maintaining ice quality and extending the lifespan of your ice machine. A comprehensivecleaning scheduleshould be based on manufacturer recommendations and real-world experience. The cleaning process involves several steps, including sanitizing the ice machine and checking for scale buildup. Understandingwater quality issuesis also crucial, as mineral content can significantly affect your ice machine’s performance. In some cases, installing awater filtration systemmay be necessary to prevent contamination.

To maintain your ice machine’s efficiency, adoptpreventative maintenance practicesthat can significantly extend its lifespan and reduce costly emergency service calls. By following these guidelines, you can protect your investment and ensure your ice machine consistently meets your business needs.

Cost Analysis: Initial Investment vs. Long-Term Value

When investing in a commercial ice maker, understanding the total cost of ownership is crucial. This involves evaluating not just the initial purchase price, but also the long-term expenses associated with operating and maintaining the equipment.

Purchase Price Comparison

The purchase price of commercial ice makers can vary widely, ranging from $1,000 to $6,000, depending on factors like the type of ice produced, daily ice output, and storage bin size. For instance, nugget ice makers are generally more expensive than standard cube ice makers. When comparing prices, it’s essential to consider your business needs to avoid paying for more capacity than you require.

Operating Costs and Efficiency

Operating costs can quickly exceed the initial investment. The energy consumption rate of your ice machine significantly impacts your monthly utility bills. Additionally, water efficiency is crucial, especially in areas with high water costs or usage restrictions. Choosing an ice maker with a properly sized storage bin can help reduce ice wastage and lower operating costs over time.

Service Plans and Warranty Considerations

Service plans represent a significant part of ownership costs. Evaluating manufacturer warranties and extended service plans is essential to understand whether they’re worth the investment. A comprehensive cost comparison between purchasing an ice machine outright versus leasing or using an ice machine service can also help you make a financially sound decision.

By considering these factors, you can make an informed decision that balances upfront costs with long-term value for your specific business needs.

Conclusion: Making the Right Commercial Ice Maker Choice

As we wrap up our comprehensive guide on commercial ice makers, it’s clear that selecting the right ice machine is crucial for your business’s success. To make an informed decision, you need to consider several key factors, including production capacity, ice type, and maintenance requirements.

When choosing a commercial ice maker, it’s essential to balance your business needs with the right type of ice machine. Whether you require a modular ice machine for high-volume production or a compact countertop dispenser for a small office, there’s a solution available to meet your needs.

Key Considerations: Consider the type of ice that suits your business, such as half cube ice for restaurants or nugget ice for healthcare facilities. Don’t forget to think about energy efficiency and maintenance accessibility to minimize long-term operating costs.

For most businesses, the KoolAire KYT0500A-161 represents the best overall value. However, your specific needs might point to a different model. Ultimately, focus on reliability, appropriate capacity, and ease of maintenance when making your commercial ice maker selection.

FAQ

What type of ice is best for my business?

The best type of ice for your business depends on your specific needs. For example, nugget ice is a popular choice for restaurants and bars because it’s chewable and can be easily consumed. On the other hand, cube ice is a versatile standard that works well for most establishments.

How do I choose the right daily production capacity for my ice maker?

To choose the right daily production capacity, consider your business’s peak hours and the amount of ice you need to produce. For instance, a busy restaurant may require an ice maker that produces at least 500 pounds of ice per day.

What is the difference between air-cooled and water-cooled condensers?

Air-cooled condensers are more common and practical, using air to cool the condenser coils. Water-cooled systems, on the other hand, use water to cool the condenser coils and are more efficient but resource-heavy.

How often should I clean my ice machine?

It’s recommended to clean your ice machine every 6 months to ensure sanitation and optimal performance. Regular cleaning can also help prevent the buildup of scale and bacteria.

What are the benefits of using a countertop ice dispenser?

Countertop ice dispensers offer convenience and hygiene, allowing customers to serve themselves. They’re also a great space-saving solution for businesses with limited counter space.

How do I determine the right storage bin size for my ice maker?

To determine the right storage bin size, consider your business’s ice usage and production capacity. A larger storage bin can help balance production and usage, reducing the need for frequent ice deliveries.