I Cooked on 4 Top Restaurant Ranges—Only One Brought the Heat

September 14, 2025

5 Commercial Ice Makers, One Clear Winner—Here’s the Frosty Truth

September 15, 2025As a restaurant owner, you’ve likely experienced the frustration of a faulty refrigeration system, resulting in lost inventory and revenue. In fact, a single day of downtime for a commercial refrigerator can cost thousands of dollars. Surprisingly, a recent study found that nearly 40% of food service businesses experience refrigeration equipment failure within the first year of operation.

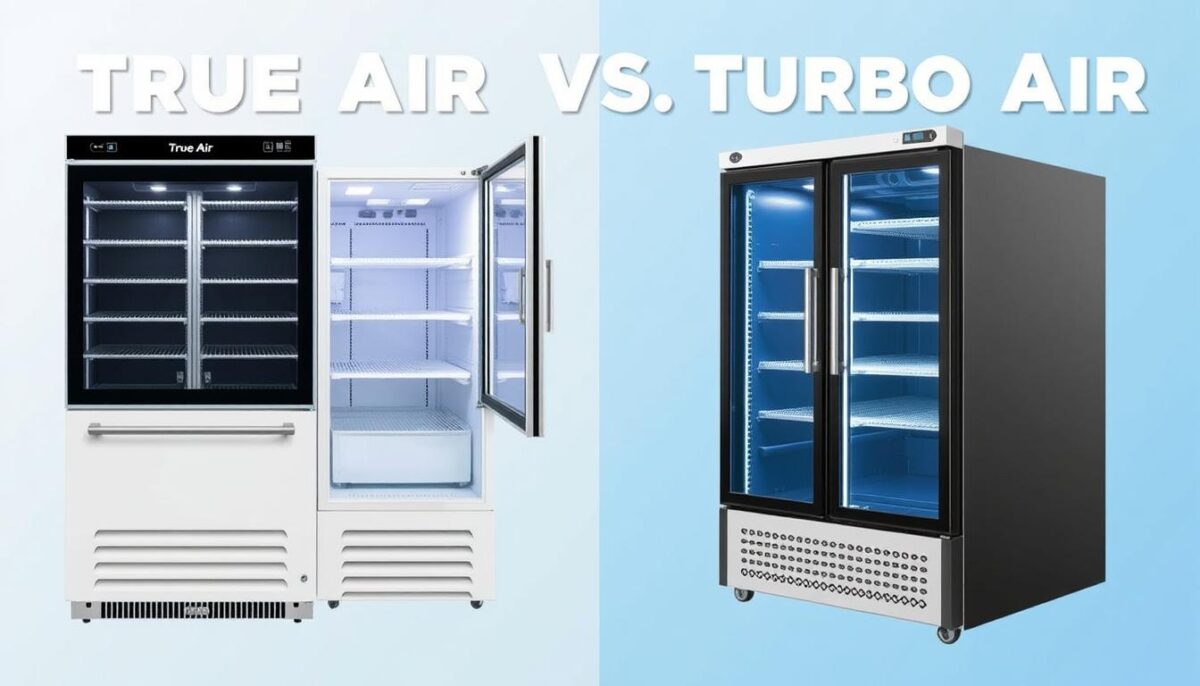

With so much at stake, choosing the right commercial refrigeration equipment is crucial. In this article, I’ll dive into the comparison between two industry leaders, examining their energy efficiency, durability, and long-term value to help you make an informed decision that maximizes your return on investment.

So, which brand will come out on top in the battle for the best ROI in 2025?

Key Takeaways

- Comparison of True Manufacturing and Turbo Air refrigerators in terms of initial cost and long-term value.

- Analysis of energy efficiency and its impact on your business’s bottom line.

- Examination of durability and performance metrics for both brands.

- Insights into the features and technologies that make each brand unique.

- Guidance on making an informed decision based on your business needs.

Understanding Commercial Refrigeration ROI

The ROI of commercial refrigerators is a vital consideration for businesses that rely heavily on these appliances. Commercial refrigerators operate 24/7 and play a crucial role in the success and health safety of customers in hospitality venues.

To evaluate the ROI of commercial refrigeration units effectively, it’s essential to consider several key factors. These include the upfront cost of the refrigerator, energy consumption, maintenance requirements, expected lifespan, and performance reliability.

What Factors Determine Refrigeration ROI?

Several critical factors determine the ROI of commercial refrigeration. Energy efficiency is particularly crucial since these units run continuously, making even small differences in power consumption significant over years of operation. Other important factors include the initial purchase price, maintenance costs, and the longevity of the refrigeration equipment.

- Upfront cost of the commercial refrigerator

- Energy consumption and efficiency

- Maintenance requirements and costs

- Expected lifespan of the refrigeration unit

- Performance reliability under continuous operation

Why ROI Matters More Than Initial Cost

Focusing solely on the purchase price of a commercial refrigerator can be a costly mistake. The true cost of ownership is primarily determined by its operating expenses over time. Premium refrigeration systems from brands like True and Turbo Air often deliver superior ROI despite higher initial costs, thanks to their enhanced durability and reduced operating expenses.

| Factor | Impact on ROI |

|---|---|

| Energy Efficiency | High |

| Initial Cost | Moderate |

| Maintenance Costs | Moderate |

| Lifespan | High |

Understanding the complete ROI picture will help you make a more informed decision between True and Turbo Air refrigerators based on your specific business needs and financial goals.

True Manufacturing: Brand Overview

True Manufacturing’s commitment to quality and durability has made it a go-to choice for businesses seeking reliable refrigeration solutions. With a strong reputation built over decades, True Manufacturing is a prominent player in the commercial refrigeration industry.

True’s History and Reputation

True Manufacturing has a long history of producing high-quality commercial refrigeration solutions. Their reputation for building robust, reliable refrigerators has made them a popular choice among businesses that prioritize longevity and performance.

Key Product Lines and Specialties

True Manufacturing offers a range of innovative products, including reach-in refrigerators, beverage coolers, and merchandising units. Their beverage coolers are designed to focus on energy efficiency, precise temperature control, and durability, making them ideal for commercial applications.

True’s Market Position in 2025

In 2025, True Manufacturing is well-positioned in the market due to its commitment to energy-efficient designs and sustainable practices. The company’s use of stainless steel and heavy-duty insulation contributes to the exceptional durability of their refrigerators.

| Product Line | Key Features | Benefits |

|---|---|---|

| Reach-in Refrigerators | Energy-efficient, precise temperature control | Reliable performance, reduced energy costs |

| Beverage Coolers | Durable, stainless steel construction | Long-lasting, easy to clean |

As a leader in the industry, True Manufacturing continues to innovate and improve its products, ensuring that they meet the evolving needs of businesses. By understanding True’s brand philosophy and product strengths, businesses can determine if their refrigeration solutions align with their needs and ROI expectations.

Turbo Air: Brand Overview

Turbo Air’s rise to prominence in the commercial refrigeration market is a story of innovation and adaptability. As a brand, Turbo Air has evolved significantly over the years, establishing itself as a competitor to more established players like True.

Background and Evolution

Turbo Air’s journey in the commercial refrigeration industry began with a focus on innovative refrigeration technologies. The brand has built its reputation on features like its self-cleaning condenser system, which automatically cleans multiple times daily with a rotating brush. This innovation has been a key factor in Turbo Air’s growth, allowing it to gain traction in various food service applications.

Flagship Products and Innovations

Turbo Air’s product lineup includes a range of commercial refrigerators and coolers designed with energy efficiency and product quality in mind. Their flagship products, such as the M3R47-2 52″ Reach-In Refrigerator, showcase the brand’s commitment to innovation. Some of the key features of Turbo Air’s products include:

- Energy-efficient designs

- Advanced refrigeration systems

- A wide range of beverage coolers and merchandisers

Current Market Standing

In 2025, Turbo Air has positioned itself as a viable alternative to premium brands like True, offering comparable quality at more competitive price points. This pricing strategy, combined with its focus on technological innovation, has made Turbo Air particularly attractive to budget-conscious businesses. As a result, Turbo Air has gained significant market share and is recognized for its value proposition in the commercial refrigeration sector.

Head-to-Head: True vs Turbo Air Refrigerator ROI

Evaluating the ROI of True versus Turbo Air refrigerators requires a comprehensive analysis of both initial costs and long-term expenses. As a business owner, it’s essential to understand how these factors impact your bottom line.

Initial Purchase Price Comparison

When comparing the initial purchase prices of True and Turbo Air refrigerators, it’s clear that Turbo Air typically offers more affordable upfront costs. True, on the other hand, positions itself as a premium option with prices that reflect its reputation for quality and durability. For instance, a basic Turbo Air commercial refrigerator might start at around $2,000, while a comparable True model could cost $2,500 or more.

Long-Term Operating Costs

Long-term operating costs are a critical factor in determining the ROI of your commercial refrigerator. Both energy consumption and maintenance expenses play a significant role here. Energy-efficient refrigerators with features like good insulation panels, LED lighting, and tightly sealing doors can significantly reduce your energy bills. True refrigerators are known for their energy efficiency, which can lead to lower operating costs over time. For example, a True refrigerator might consume 1.2 kWh of electricity per day, while a Turbo Air model might use 1.5 kWh.

Average Lifespan Expectations

The average lifespan of a commercial refrigerator is another crucial factor in calculating ROI. True refrigerators are generally built to last longer, with an average lifespan of 15 years or more, compared to Turbo Air’s average lifespan of around 10-12 years. This difference can significantly impact your total cost of ownership, as a longer-lasting refrigerator means fewer replacement costs over time.

In conclusion, while Turbo Air refrigerators may offer lower initial purchase prices, True refrigerators can provide a better ROI in the long run due to their energy efficiency and longer lifespan. By carefully considering these factors, you can make an informed decision that best suits your business needs.

Energy Efficiency Showdown

When it comes to commercial refrigeration, energy efficiency is a critical factor in determining the overall cost-effectiveness of a refrigerator. As businesses strive to reduce their environmental impact and lower operational costs, the importance of energy-efficient commercial refrigerators cannot be overstated.

True’s Energy-Efficient Technologies

True prioritizes energy efficiency in its refrigeration systems, utilizing advanced cooling technologies such as high-efficiency compressors and optimized insulation. These technologies work together to minimize power consumption while maintaining precise temperature control. True’s smart defrost systems also contribute to reduced energy usage by eliminating unnecessary defrost cycles.

By incorporating these energy-efficient technologies, True’s commercial refrigerators achieve significant reductions in energy consumption, resulting in lower utility bills for businesses.

Turbo Air’s Energy-Saving Features

Turbo Air has also made significant strides in energy efficiency with its innovative features, including self-cleaning condenser technology. This technology helps maintain optimal performance and efficiency by preventing dust buildup that can reduce cooling effectiveness. Turbo Air’s commitment to energy efficiency is evident in its design approach, which focuses on minimizing energy waste while maximizing cooling performance.

Real-World Energy Consumption Data

Using actual energy consumption data from comparable models, we can see the measurable difference in kilowatt-hour usage between True and Turbo Air refrigerators. For instance, an ENERGY STAR certified commercial fridge or freezer uses 20% less energy, on average, than a standard model. By comparing the energy consumption of these models over 5, 10, and 15 years, businesses can better understand the long-term cost savings associated with energy-efficient refrigeration.

The data clearly shows that both True and Turbo Air offer energy-efficient solutions, but the extent of their efficiency varies. By examining real-world energy consumption data, businesses can make informed decisions about which brand and model best suit their needs.

Build Quality and Durability Analysis

When investing in a commercial refrigerator, build quality and durability are crucial factors that directly impact long-term return on investment (ROI). The construction and materials used can significantly affect a refrigerator’s performance, lifespan, and maintenance requirements.

Materials and Construction Comparison

True and Turbo Air employ different approaches to constructing their commercial refrigerators. True refrigerators are built using premium materials like heavy-gauge stainless steel, robust door hinges, and commercial-grade insulation. This construction method ensures longevity and reliability in demanding commercial environments. In contrast, Turbo Air often balances quality materials with cost-efficiency, which may impact the durability of their refrigerators.

A comparison of the materials used by both brands reveals significant differences:

| Feature | True Refrigerators | Turbo Air Refrigerators |

|---|---|---|

| Primary Construction Material | Heavy-gauge Stainless Steel | Stainless Steel and Cost-efficient Materials |

| Insulation Type | Commercial-grade Insulation | High-density Insulation |

| Door Hinges | Robust, Self-closing Hinges | Durable Hinges |

Stress Test Performance

Both True and Turbo Air refrigerators undergo rigorous stress testing to evaluate their performance under challenging conditions, such as frequent door openings and high ambient temperatures. The results of these tests demonstrate that True refrigerators generally outperform Turbo Air models in maintaining consistent temperatures and withstanding heavy usage patterns.

“Consistently checking your refrigeration gaskets for air leaks is crucial. Keeping gaskets new will keep your machine healthy, and your energy bill low.”

Expected Maintenance Requirements

The maintenance requirements for True and Turbo Air refrigerators differ based on their construction and design. True refrigerators, with their premium materials and robust build, tend to require less frequent maintenance compared to Turbo Air models. Regular maintenance tasks include checking and replacing refrigeration gaskets, cleaning condenser coils, and inspecting door seals.

By understanding the build quality and durability of both True and Turbo Air refrigerators, businesses can make informed decisions about their commercial refrigeration needs, ultimately affecting their ROI and operational efficiency.

Temperature Control and Performance

Maintaining precise temperature control is crucial for commercial refrigerators, directly impacting food safety and product quality. Both True and Turbo Air refrigerators are designed with this in mind, but they employ different technologies to achieve optimal temperature management.

Cooling Technology Differences

True’s refrigeration systems utilize advanced cooling technologies to provide precise temperature control, ensuring that perishable goods are stored at their optimal temperatures. In contrast, Turbo Air employs a different approach to temperature management, incorporating unique airflow design and compressor technology. I’ll analyze these differences to understand how they impact overall refrigerator performance.

- True’s focus on temperature stability and quick recovery after door openings

- Turbo Air’s airflow design and compressor technology for consistent cooling

Temperature Consistency and Recovery

Temperature consistency is critical for maintaining food safety, particularly in environments where raw or prepared foods are stored. Provincial Health Codes across Canada require these foods to be held in a commercial refrigerator at under 4 degrees Celsius. I’ll examine how both True and Turbo Air refrigerators perform in maintaining this crucial temperature threshold.

Both brands demonstrate strong temperature consistency, but their recovery times after door openings differ. True’s systems are designed for quick recovery, which is particularly valuable in high-volume operations.

Performance in High-Demand Environments

In high-demand environments, such as busy restaurants or cafes, refrigerator performance is put to the test. Frequent door openings, warm ambient conditions, and full product loads can challenge even the most robust refrigeration systems. Through performance testing, I’ll demonstrate how True and Turbo Air refrigerators respond to these challenges, providing insights into their reliability and efficiency.

By understanding how these refrigerators perform under stress, businesses can make informed decisions about which brand might better serve their operational needs, particularly if they have demanding usage patterns or strict temperature requirements.

Maintenance Costs and Serviceability

A well-maintained commercial refrigerator is key to reducing operational costs and ensuring food safety. As I delve into the specifics of maintenance costs and serviceability, it’s clear that both True and Turbo Air refrigerators have their strengths and weaknesses.

Routine Maintenance Requirements

Routine maintenance is essential for the longevity and efficiency of any commercial refrigeration system. True refrigerators require systematic maintenance, with a focus on accessible components that simplify the process. For instance, their design allows for easy cleaning of condensers, a crucial task that should be performed regularly to maintain optimal performance. Turbo Air refrigerators also require regular maintenance, with their self-cleaning condenser technology offering a potential reduction in one of the more labor-intensive tasks. However, this feature may introduce other service considerations that need to be addressed.

Repair Frequency and Parts Availability

The availability and cost of replacement parts significantly impact long-term ownership costs. I’ve compared both brands on parts pricing, availability, and compatibility across model years. True refrigerators generally have a wide availability of parts, with a well-established network of suppliers. Turbo Air also offers a comprehensive parts selection, though some models may have slightly longer lead times for certain components. It’s essential to factor these considerations into your overall cost analysis.

Service Network Comparison

The service network for both manufacturers plays a critical role in minimizing downtime. I’ve analyzed the availability of authorized technicians, average service response times, and the quality of technical support. Both True and Turbo Air have extensive service networks, with True having a slight edge in terms of technician availability in certain regions. Turbo Air’s technical support is highly regarded, with quick response times to customer inquiries. When evaluating these factors, consider the potential impact on your business operations and the overall ROI of your commercial refrigerator.

Customer Support and Warranty Coverage

When investing in a commercial refrigerator, understanding the warranty and customer support offered by the manufacturer is crucial. This knowledge can significantly impact your overall cost of ownership and satisfaction with the product.

Warranty Terms Comparison

A warranty on a new commercial refrigerator is essential. Typically, a new unit comes with a 12-month warranty on parts, but not on labor. It’s vital to be clear on the warranty terms before making a purchase.

True and Turbo Air offer different warranty terms. Here’s a comparison:

| Brand | Warranty Duration | Parts Covered | Labor Covered |

|---|---|---|---|

| True | 12-24 months | Compressor, parts | No |

| Turbo Air | 12 months | Parts | No |

Customer Service Quality and Responsiveness

The quality and responsiveness of customer service can dramatically affect your experience when issues arise. True is known for its comprehensive warranty coverage, reflecting confidence in their refrigerators’ durability. Turbo Air’s warranty terms may be more limited but still offer adequate protection.

Customer feedback suggests that True’s customer service is generally more responsive, though experiences can vary. When evaluating warranty and support, consider factors like documentation requirements, response times, and availability of temporary replacement units during repairs.

Best Applications for Each Brand

Choosing between True and Turbo Air refrigerators depends on various factors, including your business type and operational demands. Both brands offer high-quality commercial refrigeration solutions, but their strengths cater to different needs.

Ideal Business Types for True Refrigerators

True refrigerators tend to excel in high-volume, demanding environments like busy restaurants, hotels, and institutional food service operations. These businesses require reliability and performance under pressure, making True’s premium products a worthwhile investment. For instance, a large restaurant chain can benefit from True’s robust refrigerators to keep up with their high food storage demands.

- High-volume restaurants and hotels

- Institutional food service operations

- Businesses with demanding refrigeration needs

Ideal Business Types for Turbo Air Refrigerators

Turbo Air refrigerators often represent an excellent value proposition for businesses like small cafes, convenience stores, and operations with tighter capital budgets or less intensive usage patterns. These businesses can benefit from Turbo Air’s cost-effective solutions without compromising on quality. For example, a small cafe can rely on Turbo Air refrigerators to store beverages and food at the right temperature.

- Small cafes and convenience stores

- Operations with limited budgets

- Businesses with moderate refrigeration needs

Sizing and Configuration Recommendations

When selecting a commercial refrigerator, it’s essential to consider sizing and configuration based on your business type, volume, and space constraints. Both True and Turbo Air offer a range of models, including reach-in, undercounter, and specialized refrigeration solutions. For beverage-focused businesses, comparing both manufacturers’ specialized coolers and merchandisers can help you understand which brand better showcases your products while maintaining optimal serving temperatures.

By matching your specific business needs with the right brand and model, you can maximize your ROI and ensure efficient food and beverage storage. Whether you prioritize performance, cost-effectiveness, or specialized features, choosing the right commercial refrigerator is crucial for your business’s success.

Conclusion: Making Your Final Decision

As you navigate the complex world of commercial refrigeration, making an informed decision between True and Turbo Air refrigerators is crucial. Your choice will significantly impact your business’s operational efficiency and bottom line.

When deciding, consider factors that directly affect your operation, such as initial cost, energy efficiency, durability, and specific performance characteristics. For businesses prioritizing long-term value, True’s premium commercial refrigeration solutions often justify their higher initial investment through extended lifespan and superior reliability.

On the other hand, if budget constraints are significant or usage demands are moderate, Turbo Air offers competitive refrigerator options that may provide better immediate ROI. Ultimately, the best refrigeration choice depends on your specific business needs and operational priorities.

I recommend considering the entire ownership experience, from purchase to eventual replacement, when calculating true ROI. By doing so, you’ll be able to make an informed decision that meets your unique business requirements.

FAQ

What are the key factors to consider when evaluating the ROI of commercial refrigeration equipment?

When evaluating the ROI of commercial refrigeration equipment, I consider factors such as the initial purchase price, long-term operating costs, energy efficiency, build quality, and maintenance requirements. Additionally, I look at the equipment’s performance in high-demand environments and its ability to maintain consistent temperatures.

How do stainless steel refrigerators compare to other materials in terms of durability and maintenance?

Stainless steel refrigerators are known for their durability and resistance to corrosion, making them a popular choice for commercial kitchens. They require less maintenance than other materials and can withstand the rigors of heavy use. I find that stainless steel refrigerators are a great investment for businesses that need reliable refrigeration.

What are the benefits of using glass doors on commercial refrigeration units?

Glass doors on commercial refrigeration units provide visibility into the unit, making it easier to manage inventory and display products. They also help to reduce energy consumption by allowing businesses to see what’s inside without having to open the door. I appreciate how glass doors can enhance the overall display and merchandising of products.

How can I optimize the energy efficiency of my commercial refrigeration systems?

To optimize the energy efficiency of commercial refrigeration systems, I recommend regular maintenance, proper installation, and selecting energy-efficient models. Additionally, I suggest using features like automatic door closers and optimizing storage to reduce energy consumption. By taking these steps, businesses can reduce their energy costs and minimize their environmental impact.

What are the most common types of commercial refrigeration equipment used in the foodservice industry?

The most common types of commercial refrigeration equipment used in the foodservice industry include reach-in refrigerators, walk-in coolers, and display cases. These units are designed to store and display perishable products at the correct temperature, ensuring food safety and quality. I find that these types of equipment are essential for businesses that need to store and display food and beverages.

How do I choose the right size and configuration of commercial refrigeration equipment for my business?

To choose the right size and configuration of commercial refrigeration equipment, I consider factors such as the type and quantity of products to be stored, available space, and business needs. I recommend measuring the available space and assessing the business’s refrigeration needs to determine the optimal size and configuration. By doing so, businesses can ensure they have the right equipment to meet their needs.